How much do you know about post-weld heat treatments?

Heat treatment is an important part in the high quality welding project. These heat treatment measures have greatly reduced the impact of thermal stress generated during the welding process. Thermal stress occurs because even though the metal is an extremely rugged material, it is still somewhat vulnerable to the extremely high temperatures generated during the welding process. Through careful study, TICO deeply understands the post-weld heat treatments(PWHT) and why it is so important.

|

Importance of high quality welding

Welding is an indispensable tool in the pipeline construction and manufacturing process. The molten pool usually experiences sudden and extreme temperature increase. As it begins to cool, the metal will be subject to shrinking caused by the sudden thermal stress, which will have a negative impact on the quality of the product and the chemical structure of the steel. If this problem is not solved, the weldment can not perform its function, potentially leading to disastrous effects.

What causes thermal stress?

The causes of thermal stress are varied and complicated. But fortunately, after the effective application of post-weld heat treatments, thermal stress can be largely reversed or eliminated. Some possible causes of thermal stress include the following.

- The thermal gradient caused by layer of metal forms across different parts of welding line.

- Metals have been affected in many areas.

- The majority of the steel is located in or around the ambient temperature.

- The results of rapid cooling changed the steel's macro structure, which could make the steel weaker and less effective.

PWHT can eliminate these potential problems by heating and cooling the welding area. This will give the steel structure enough time to return to its original state. TICO professional group has incomparable wealth of experience in this process.

Factors affect the stress level of steel

The quality of metal is greatly influenced by the rate at which is heated and cooled. Post weld heat treatment works by lowering the temperature of the metal to make it back to its original level. The thicker the metal is, the more likely to be affected by the residual stress. Other factors that affect the stress level of steel include:

- When two different materials are welded together, their structure has the ability to change the structure of the original metal.

- If the hydrogen is introduced in the welding process, the metal will become easy to crack and rust.

- If the weld area is harder than the rest of the steel, the potential threat of corrosion and grinding will increase.

- When the shape of the welded parts is different, thermal gradients can be formed across various parts of the steel.

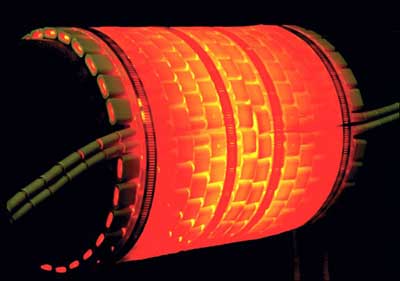

Heating method for PWHT

- Fuel heating method: Coal fired heating | Liquid fuel heating | gas fuel heating

- Electrical heating method: Electrical heating element heating | workpiece resistance heating | workpiece induction heating | heating medium resistance heating

- Energy heating method: Laser beam heating | electron beam heating

A reliable results

In short, post weld heat treatment is a critical process in the steel manufacturing industry. Without this technology, there is no way to ensure that the quality of metal production maintain the highest level. Pressure vessels and other structural steel equipment cannot be allowed to fail. However, through the post weld heat treatment, the tensile strength andcreep limit of metals have been guaranteed over the years.