How could you not know the knowledge of the oil pipeline

Special terminology relating to petroleum pipe

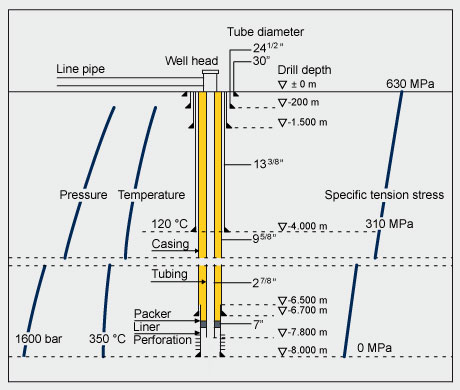

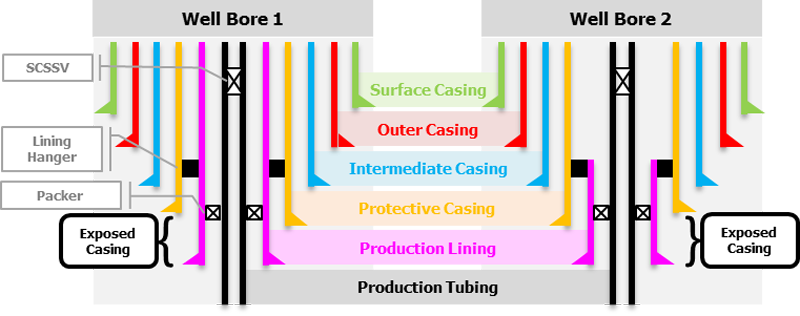

Casing: A tube used as lining wall drilled from the ground surface into the drilled hole to prevent borehole collapse.

Casing: A tube used as lining wall drilled from the ground surface into the drilled hole to prevent borehole collapse.

Tubing: A tube used for extracting oil, gas extraction, waterflooding and acid fracturing.

Drill pipe: A pipe used for drilling.

Line pipe: A pipe used to transport oil or gas.

Collar: A cylindrical body for connecting two threaded tubes which have internal threads.

API thread: A pipe thread under the standard of API5B, includes round thread tubing, casing short round thread casing, long thread, buttress casing thread, thread pipe and so on.

Special buckle: non - API thread buckle with special sealing performance, connecting performance and other properties.

Failure: Produce some phenomena including deformation, fracture, surface damage and loss of the original functon under certain service conditions.

The main failure modes of tubing and casing are crushing, slippage, rupture, leakage, corrosion, adhesion, wear and tear.

Classification and steel grade of tubing

Tubing is divided into flat tubing (NU), thickened tubing (EU) and integral tubing.

Flat tubing: The pipe end is directly cutting thread and connecting with the screw thread but without thickening.

Thickened tubing: After the two pipe ends are thickened, cut thread and connect collar.

Integral tubing: One end of pipe through inside thickening with cutting thread, the other end through outside thickening with cutting thread, then connect them directly but without collar.

Tubing steel grades are: H40, J55, N80, L80, C90, T95, P110.

- N80 is divided into N80-1 and N80Q. The same point of the two is same tensile properties. the difference between the two is delivery status and impact performance.

- N80-1 deliver in normalized condition or when the final rolling temperature is greater than the critical temperature Ar3 and the tension reducing diameter passes through the air cooling, hot rolling can replace normalizing. The N80Q must pass through empering treatment, Impact work shall be in accordance with API5CT and shall be subject to nondestructive testing.

- L80 is divided into L80-1, L80-9Cr and L80-13Cr., their mechanical properties and delivery status are the same, the difference in the use, production difficulty and price.

- L80-1 is the common type, L80-9Cr and L80-13Cr are high corrosion resistant tubing. Production is difficult, expensive, usually used for heavy oil wells. C90 and T95 were divided into type 1 and type 2, namely C90-1, C90-2 and T95-1, T95-2.

Classification and function of casing

Surface casing: It is mainly used for the first time to drill the soft layer of the surface to the base rock, and in order to seal this part of the formation will not collapse, you need surface casing to seal. The depth of the pipe depends on the depth of the soft layer, usually 80~1500m. External pressure and internal pressure of surface casing is not large, so generally use K55 steel grade or N80 steel grade.

Technical casing: When encounter the collapse layer, oil layer, gas layer, water layer, leakage layer, salt gypsum layer and other complex parts, need to be sealed under the technical casing, otherwise the drilling can not be carried out.

Oil layer casing: When the well is drilled to the target layer, casing is used for sealing oil layer and upper exposed strata. The depth of the casing in the casing is the deepest, and the mechanical properties and sealing performance requirements are the highest. The use of steel grade has K55, N80, P110, Q125, V150 and so on.

Classification of line pipe

Pipeline is used to transport oil, refined oil, natural gas and water pipelines, etc in oil and gas industry. It is divided into the main transmission line, feeder line and urban pipeline network. The main pipeline is usually specifications for 406 ~ 1219mm, the wall thickness is 10 ~ 25mm; The general specification for the feeder line and the urban pipe network is 114 ~ 700mm, the wall thickness is 6 ~ 20mm. There are welded steel pipe, seamless steel pipe, and the use of welded steel pipe is more than that of seamless steel pipe.