Does the oil pipeline need anti-corrosion protection

Why pipeline need anti-corrosion

Pipelines, transporting oil or gas, are mostly in a complex soil environment. The transport medium is also corrosive, so the inner wall and outer wall of the pipeline are likely to be corroded. Once the pipeline is corroded and perforated, it leads to oil and gas leakage. Not only make the transport disruption, but also pollute the environment, and may even cause a fire, resulting in harm. In other words, it's necessary that pipeline needs anti-corrosion.

Pipelines, transporting oil or gas, are mostly in a complex soil environment. The transport medium is also corrosive, so the inner wall and outer wall of the pipeline are likely to be corroded. Once the pipeline is corroded and perforated, it leads to oil and gas leakage. Not only make the transport disruption, but also pollute the environment, and may even cause a fire, resulting in harm. In other words, it's necessary that pipeline needs anti-corrosion.

In the pipeline system, the definition of corrosion is: Based on the specific pipeline environment, all metal and nonmetal materials in the pipeline system happen to the chemical reactions, electrochemical reactions and microbial corrosion. This reaction can lead to damage and loss of pipeline structure and other materials. In addition to the direct damage to the material, the pipeline damage caused by corrosion products may also be considered as corrosion damage. Whether the corrosion of pipelines will spread or not depends on the corrosion resistance and the corrosion resistance of the existing pipeline materials. Temperature, the concentration of corrosive medium and the condition of stress can affect the degree of pipeline corrosion.

Method of pipeline corrosion protection

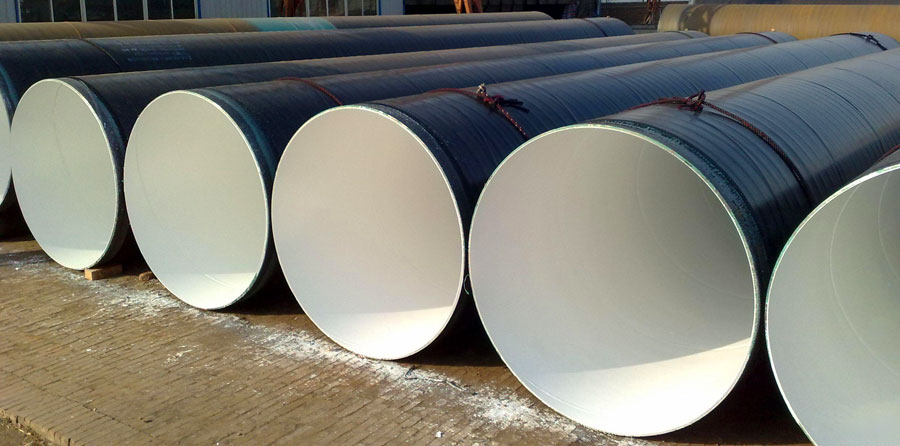

Coating anti-corrosion

Dense coating evenly coated in the rust on the surface of metal pipes, which isolated from all kinds of corrosive media, is one of the most basic methods of pipeline corrosion protection. And now, pipeline anti-corrosion coatings are more and more used in composite or composite structures.

Electrical protection

Change the potential of the metal relative to the surrounding medium to make the metal free from corrosion. The electrical protection of long distance pipeline generally refers to the method of cathode protection. cathode protection technology is a kind of electrochemical protection technology. The principle is that an applied current is applied to the surface of the corroded metal structure to prevent electron transfer and avoid or reduce the occurrence of corrosion.

Precautions for corrosion protection and cathode protection of pipeline

- In the selection of the oil and gas pipelines, it should avoid the area of the underground stray current interference. When the electric railway is parallel to the oil and gas pipelines, it should keep a certain distance. Because of disturbed by the underground stray current interference in the pipeline, drainage measures should be taken.

- The cathode protection of oil pipeline should be reached or below -0.85V, but the lowest potential is not less than -1.50V.

- Pipeline management unit should regularly detect pipeline anti-corrosion and the situation of cathode protection. Repair the damaged layer in time, and adjust the parameters of the cathode protection in the best condition.

- The potential of pipeline cathode protection is not up to the requirements, and the corrosion layer happen to aging, that should be timely overhauled for anti-corrosion layer.

- Both ends of the pipeline in pump station, should be taken measures to prevent lightning inducing current. The lightning protection measures should not affect the effect of pipeline cathode protection.

- When the pipeline needs to be filled with insulation layer, the surface of the steel pipe should be coated with a good anti-corrosive insulation layer. Outside the insulation layer has a good waterproof layer.

- The pump station in the oil tank and underground pipelines, should be implemented cathode protection. The outer surface coating color and marking should conform to the requirements of relevant standards.