Development trend of global continuous pipe drilling technology

In recent years, many old oilfields at home and abroad have put forward the demand of using the continuous pipe for cutting window sidetrack drilling and deepen drilling. Along with the development of coiled tubing drilling, it will replace conventional drilling technology in certain areas or under certain conditions. What’s more it will lead to drilling technology revolution, so the continuous pipe drilling system has become a hot technology which urgently need to be understood and mastered.

The structure of coiled tubing drilling system

Since 1962, California oil company and Bowen tool company jointly developed the first portable continuous tube machine used in petroleum industry, it has been 52 years of history. From the birth of coiled tubing, people have been exploring its use in drilling services.

At the beginning of 1990s, the French company using continuous pipe technology in old wells deepened, the United States company using the continuous tube to perform underbalanced drilling test, which has greatly promoted the development of coiled tubing drilling technology. As a low cost, high efficiency, safe and reliable drilling new technology, the coiled tubing drilling technology has become the hot technology in the field of drilling.

Continuous tube system

It turns the conventional drill pipe or tubing into work string with continuous and no string, which is contained, fixed, and carried by a work drum like a cable. The working drum has the function of receiving and releasing continuous pipes during construction. One end of the well is connected with a downhole tool string, and downhole operation is carried out. In the continuous pipe work process, it can maintain the uninterrupted working fluid circulation. This is a great advantage of continuous tube equipment, making its construction with pressure easy and easy to control, so the continuous pipe equipment has better pressure and less balanced construction capacity.

Well control system

In the drilling process, blowout preventer(BOP) is used to effectively control the pressure in the well, and it is a special equipment to prevent blowout accidents. In the operation of continuous pipe under balanced drilling, blowout preventer is more important. Two sets of BOP sets are usually required. One is for continuous pipes, and the other for BHA. A typical BOP stack for a continuous pipe consists of a blowout preventer, a fully enclosed gate, a shear ram, a slip gate, a half gate, a well drain pipe with four separate valves, and a manifold.

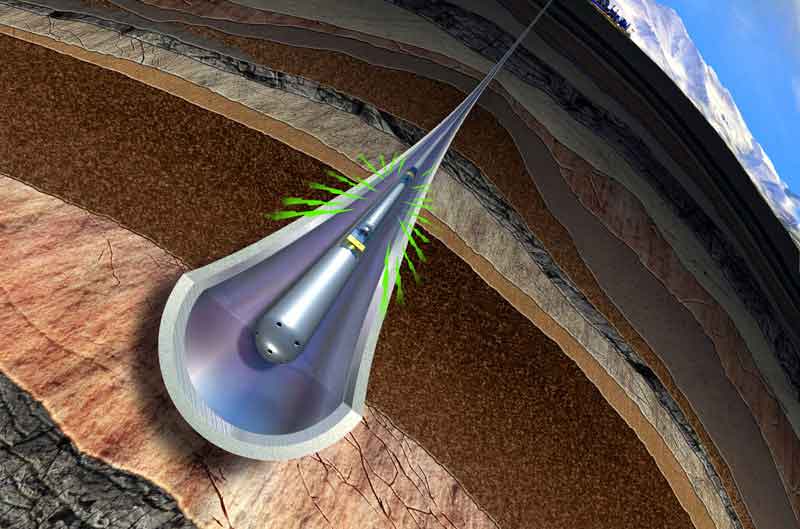

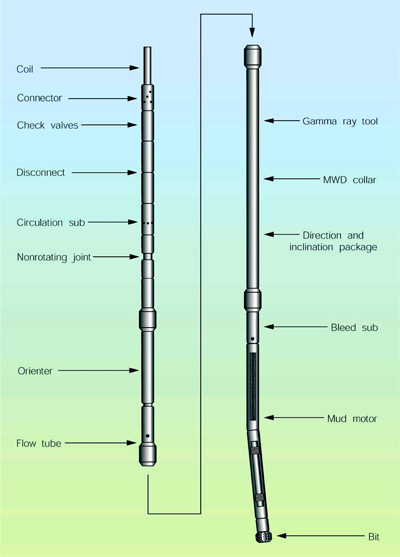

Downhole drilling assembly and guiding system

Downhole drilling assembly and guiding system is the core that continuous tube realizes directional drilling. Control the direction and the angle of the drilling tool according to information from bottom of well to realize borehole trajectory control in drilling.

According to the transfer data from the bottom of the well, there are two methods:

- If drilling operation adopts single phase drilling fluid, drilling fluid pulse system is used to transmit measured data.

- If drilling operations using two phase drilling fluid(containing gas), continuous tube cable system will transmit measured data. For underbalanced drilling, the latter is more ideal, because it is not affected by the type of drilling fluid.

Data monitoring system

The key parameters need to be monitored and recorded in the drill operation, so data monitoring system play an important role to monitor the residual fatigue life of the continuous pipe string, including operation parameters of continuous pipe equipment, drilling parameters and geological parameters of logging while drilling.

Three phase separator, oil gas recovery device and spark ignition system

A three-phase separator is a component of a coiled tubing drilling fluid that controls the flow of fluid, liquid, gas, and gas. In general installing a desander before the device, ensure the three-phase separator is in normal working condition for a long time. The recovery of crude oil and natural gas from drilling fluids can also be enhanced by the use of a recovery system to increase the utilization of formation oil and gas, but the corresponding cost will increase. The injection ignition system is generally aimed at non recoverable or no well installed oil and gas recovery systems that the oil and gas returned from the well will be ignited and burned out.

Application and development of coiled tubing drilling technology

At present, the world's oil drilling technology is mainly to find new oil and gas reservoirs, protect reservoir and improve the recovery rate to achieve safe, efficient, low cost. The development trend of coiled tubing drilling machine is in line with the development trend of drilling technology in the world, mainly reflected in the direction of the pipe diameter to develop and control to the direction of intelligent development.

At present, the coiled tubing drilling technology, including drilling system and technology is in the further development, improvement and promotion stage. It can rapidly develop and promote, mainly because it has low cost, safe operation, environmental protection and easy to realize the advantages of automation. It has strong competitiveness in directional drilling and underbalanced drilling. It is foreseeable that the coiled tubing drilling will become the main drilling equipment in twenty-first century.